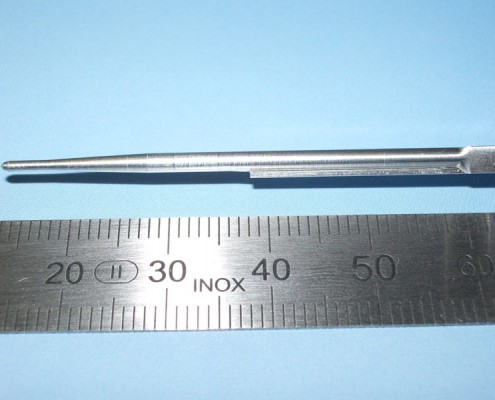

- use of Ø20 μm milling cutter

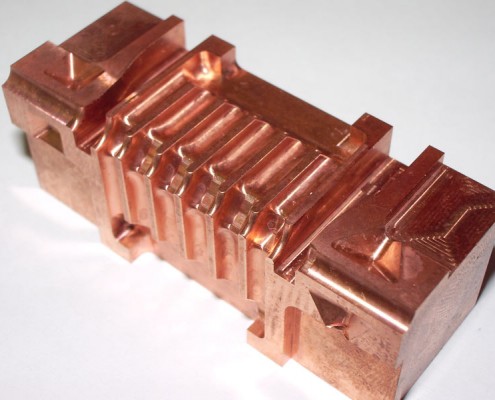

- Milling of 10-μm wide electrodes.

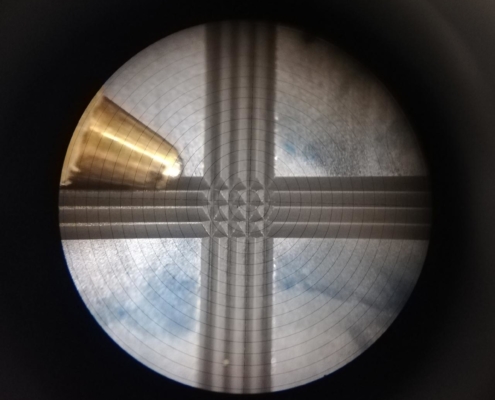

- Ra 0.2 even in case of 5 axis coordinated simultaneously

- Coordinated grinding to calibrate high-precision parts.

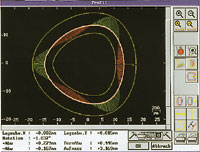

- Actual and visible 0.2 μm increment (automatic 0.01 μm measuring system)

We are confronted with parts requiring 1 week of programming.

Our machine is equipped with EROWA chuck and is therefore suitable for machining parts mounted on EROWA holder.

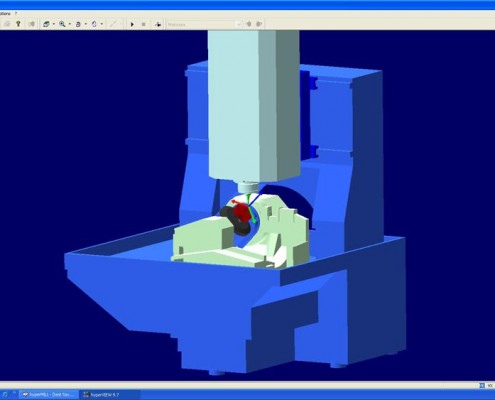

MATSUURA LX0 machine:

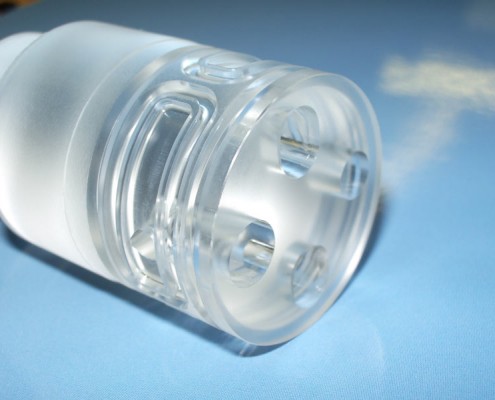

- 5 axis coordinated simultaneously

- 5 linear motor drive axis

- Spindle 60,000 rpm

- Up to 20-Kg parts and 200 x 250 x 250 stroke

- 5.5 ton cast-iron thermo-stabilized frame in cast iron

- automatic 0.01 μm measuring system and 0.1 μm travel at 10th (excellent for surface finishes)

- Blum Nano laser for milling cutters over ø 0.1

- Pico Blum sensor for milling cutters below ø 0.1

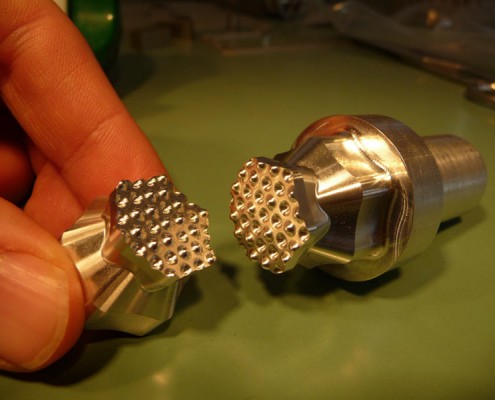

- Possibility of milling with micro-milling cutters all steels treated up to 70 HRC

- Open Mind licence (HyperMill) for programming in 5 axis coordinated simultaneously and for milling with short tools.

- Machinable materials: hardened steel, copper and Sparkal for electrodes, titanium, Inconel, Astoloy, cobalt-chromium, non-sintered zirconia, molybdenum, sintered ceramics machinable with diamond tools, etc.

- Three-dimensional measurements of the part in the machine through Blum’s “Formcontrol” software with control report.

- Zeiss 3D Control

- Three-dimensional measurements of the part in the machine through Blum’s “Formcontrol” software with control report.