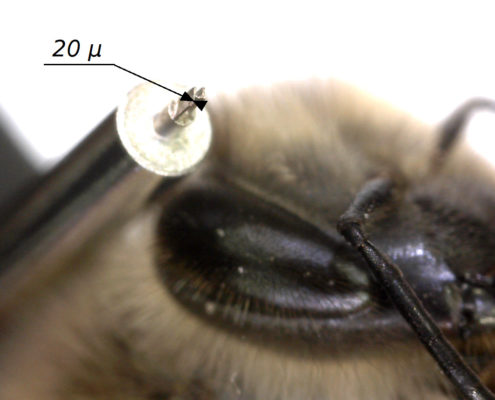

The company manufactures its own electrodes up to10 μm-wide and machine 20 μm-wide shapes. Some applications require up to about fifty electrodes on a Ø1 part.

The lowest machine settings allow us to use 2.5 μm gaps and therefore to achieve very high-precision machining.

We are used to machining parts requiring die sinking EDM in 4 axis coordinated simultaneously. Some parts may involve 6-week machining.

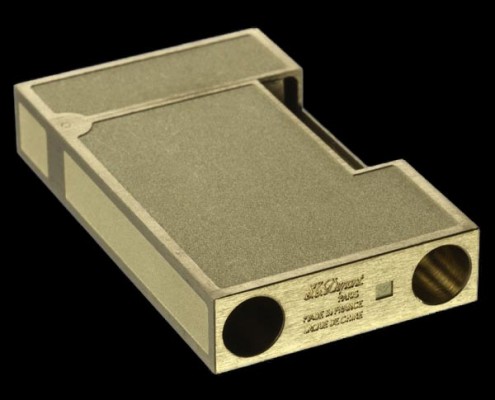

Since 1967 the company has mass-produced parts by using die sinking EDM.

Around 2,000,000 ST DUPONT lighters have been machined (on the area coated with Chinese lacquer).

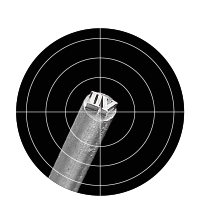

Machining of slits from 20 to 150 μm-wide to calibrate eddy current probes and of holes with a flat bottom to calibrate ultrasonic testing equipment. These standard defects are used for Non-Destructive Testing (NDT).

8 wire cutting Charmilles Technologies, 3 Sarix.

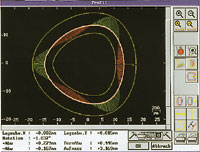

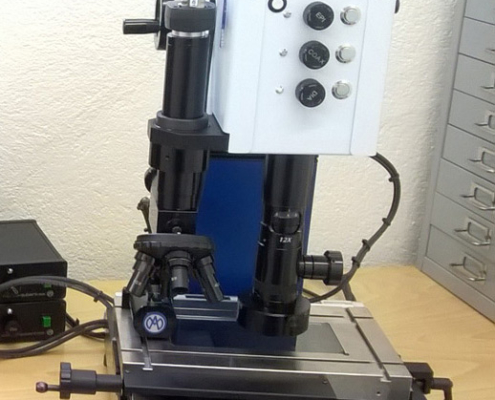

The company has several types of quality control by mechanical probing (3D Zeiss, conventional means of control) and has a lot of optical means (Marcel Aubert, camera, microscope on machine…).